Silk Structure: From Molecular Threads to Timeless Fabric

Silk structure defines why this material has been prized across cultures for thousands of years. Understanding silk structure helps designers scientists and consumers appreciate its unique blend of strength softness and sheen. This article explores silk structure at multiple scales from molecular chains to woven textiles and highlights how this knowledge informs fashion technology sustainability and care. For more trends and in depth guides visit styleradarpoint.com where we track style science and material innovation.

What Is Silk Structure

When people talk about silk they often mean the finished fabric. Silk structure however begins at a microscopic level. Natural silk produced by silkworms and some spiders is a protein based fiber made mainly of two components fibroin and sericin. Fibroin is the structural protein that forms long chains and provides mechanical strength. Sericin is a glue like coating that holds the fibroin fibers together inside the cocoon and influences dyeing and processing.

Silk structure is hierarchical. That means the arrangement and interaction of molecules determine nanoscale features which in turn determine microscale fiber behavior and finally macroscopic textile properties. Each level matters when you want a fabric that drapes well resists wear or interacts with moisture and light in particular ways.

Molecular Building Blocks

At the molecular level silk structure is dominated by fibroin chains. These chains are rich in certain amino acids such as glycine alanine and serine. The sequence of amino acids allows sections of the chain to line up and form crystalline regions known as beta sheet structures. Between these crystalline blocks lie more disordered amorphous regions. The interplay between ordered and disordered zones gives silk both high strength and elasticity.

Beta sheet stacking creates tight hydrogen bonding networks that resist tensile forces. The amorphous regions allow molecular slippage which is important for toughness. This arrangement means silk can absorb energy without cracking which is one reason why some natural silks rival synthetic fibers in performance. The presence of sericin on raw silk affects how dyes adhere and how the fiber interacts with water and cleaning agents.

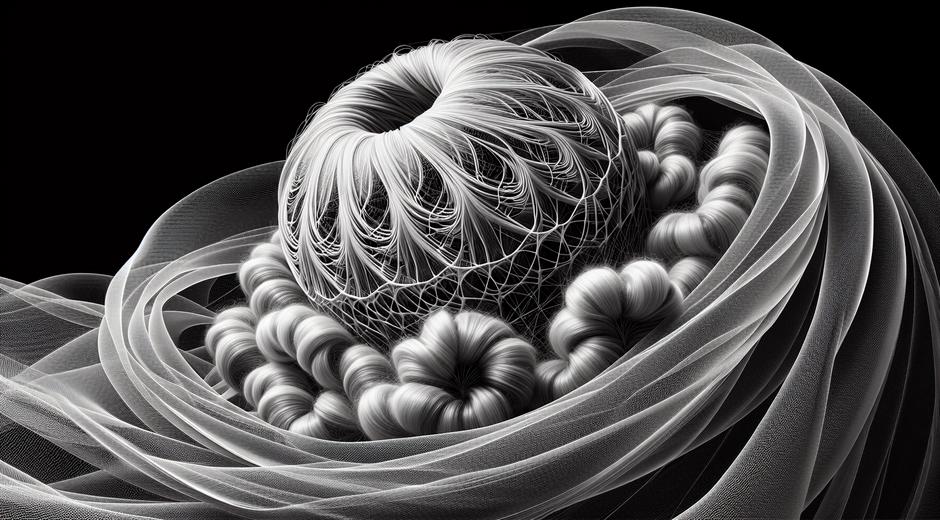

Hierarchical Architecture

Moving up in scale the single silk fiber is a composite of micro fibrils and nanofibrils. These tiny structural elements are organized along the fiber axis. The microstructure often includes pores and channels which affect moisture transport and thermal insulation. At the textile scale the way fibers are spun woven or knitted changes drape tensile behavior and surface sheen.

Silk structure also influences how light interacts with the fabric. The smooth aligned crystalline zones produce the characteristic shine known as luster. Different weaving patterns and finishing treatments change how aligned those regions are at the surface and therefore how bright the fabric looks under various lighting conditions.

How Structure Affects Physical Properties

The unique silk structure produces a set of properties that are highly desirable in apparel and high performance textiles. Key features include tensile strength high elongation at break and remarkable toughness. Silk structure also yields excellent thermal regulation. Because of its porous microstructure silk can trap air which provides insulation while still allowing moisture to evaporate. This makes silk comfortable in varied climates.

Silk structure also gives good moisture management. The protein nature of the fiber can absorb a small percentage of its weight in water which helps control humidity close to the skin. Additionally silk is naturally smooth and low friction which reduces wear on delicate materials and feels luxurious against the skin.

Silk Structure and Color

Dye uptake and color fastness are influenced by the sericin layer and by the chemical groups present in fibroin. Removing sericin in a process called degumming exposes the fibroin and can change how dyes bind. The nanoscale arrangement of beta sheet crystals can also scatter light in specific ways producing iridescence or enhanced luster. Fabric finishing techniques that adjust surface roughness will alter the perceived color and sheen without changing the dye used.

Silk in Fashion and Design

Designers exploit silk structure to achieve desired silhouettes and movement. Because silk fibers can be produced with varying diameters and filament lengths designers choose particular weaves to create flowing gowns crisp blouses or draping scarves. Technical knowledge of silk structure allows designers to select processing methods that preserve strength while enhancing softness and sheen.

Silk also lends itself to print and embroidery because its surface accommodates fine detail. Understanding the underlying silk structure helps in selecting the right printing inks and embroidery threads to avoid damaging the fiber. As fashion moves toward greater transparency about materials consumers want both beauty and traceability which is prompting brands to highlight the role of silk structure in product performance.

Biomedical and High Tech Uses

Beyond fashion silk structure has attracted attention in medicine and engineering. Because silk fibroin is biocompatible and biodegradable researchers use silk based films scaffolds and hydrogels for tissue engineering wound healing and controlled release of drugs. The ability to tune silk structure from stiff crystalline to soft amorphous makes it a versatile platform for biomedical devices.

Silk structure is also studied in sensors and optics. Its optical clarity and mechanical strength support applications in flexible electronics and wearable devices. For sports and performance textiles silk structure can be engineered to balance moisture control and breathability while maintaining light weight and comfort which aligns with consumer interest in better performing apparel. For insight into sports and performance trends see SportSoulPulse.com which covers innovation across active lifestyle sectors.

Care and Maintenance Based on Structure

Because silk structure can be sensitive to strong alkaline cleaners and high temperatures proper care preserves both strength and luster. Gentle washing in mild detergent and cool water helps maintain the beta sheet arrangement and prevents excessive fiber swelling. Avoiding prolonged exposure to direct sunlight reduces photodegradation of amino acid residues which can weaken fibers over time.

Storage and handling also matter. Silk structure is susceptible to abrasion so storing garments separately or using protective covers reduces surface wear. For high value items professional cleaning may be preferable to home methods. Knowledge of silk structure aids consumers in making informed choices that extend product life while maintaining the look and tactile quality that make silk so desirable.

Sustainability and Future Directions

As demand for sustainable materials grows researchers and manufacturers examine silk structure for clues on reducing environmental impact. Innovations include cultivating non mulberry silks developing low impact degumming processes and creating recombinant silk proteins using biotechnology. Tailoring silk structure at the molecular level enables materials with targeted performance while reducing waste and energy use.

Future directions include hybrid materials that combine silk structure with other natural or synthetic elements to create fabrics with enhanced durability moisture responsiveness or even active functions such as temperature adaptive behavior. Understanding the science behind silk structure is central to these advances and will shape how designers engineers and brands use silk in the decades ahead.

Conclusion

Silk structure is a rich field that links molecular science with tangible benefits for fashion health and technology. From the arrangement of amino acids to the way fibers are woven into fabric every level of structure contributes to silk characteristics that are sought after by designers manufacturers and consumers alike. By appreciating and studying silk structure we can preserve traditional craft improve product performance and innovate new applications that honor the natural elegance of this remarkable material.